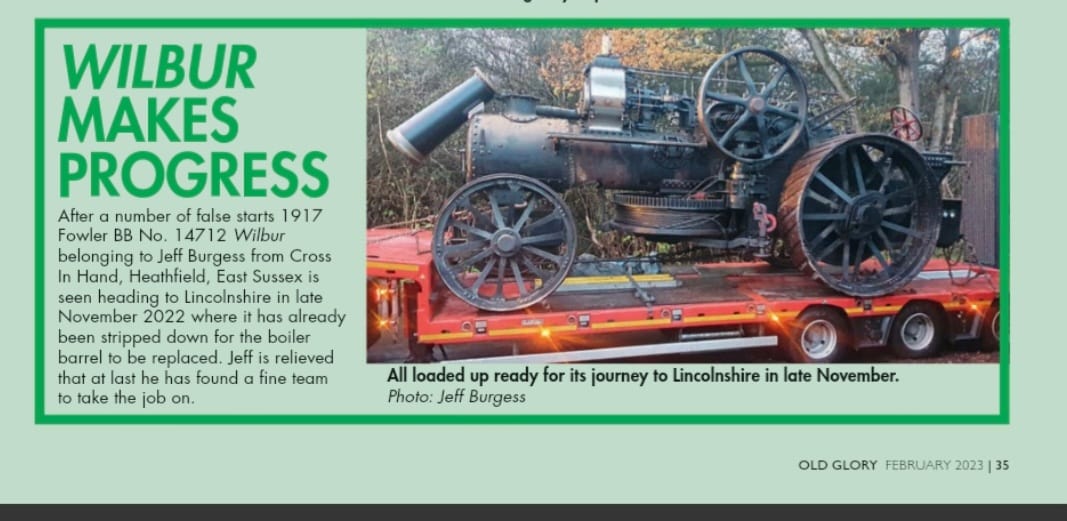

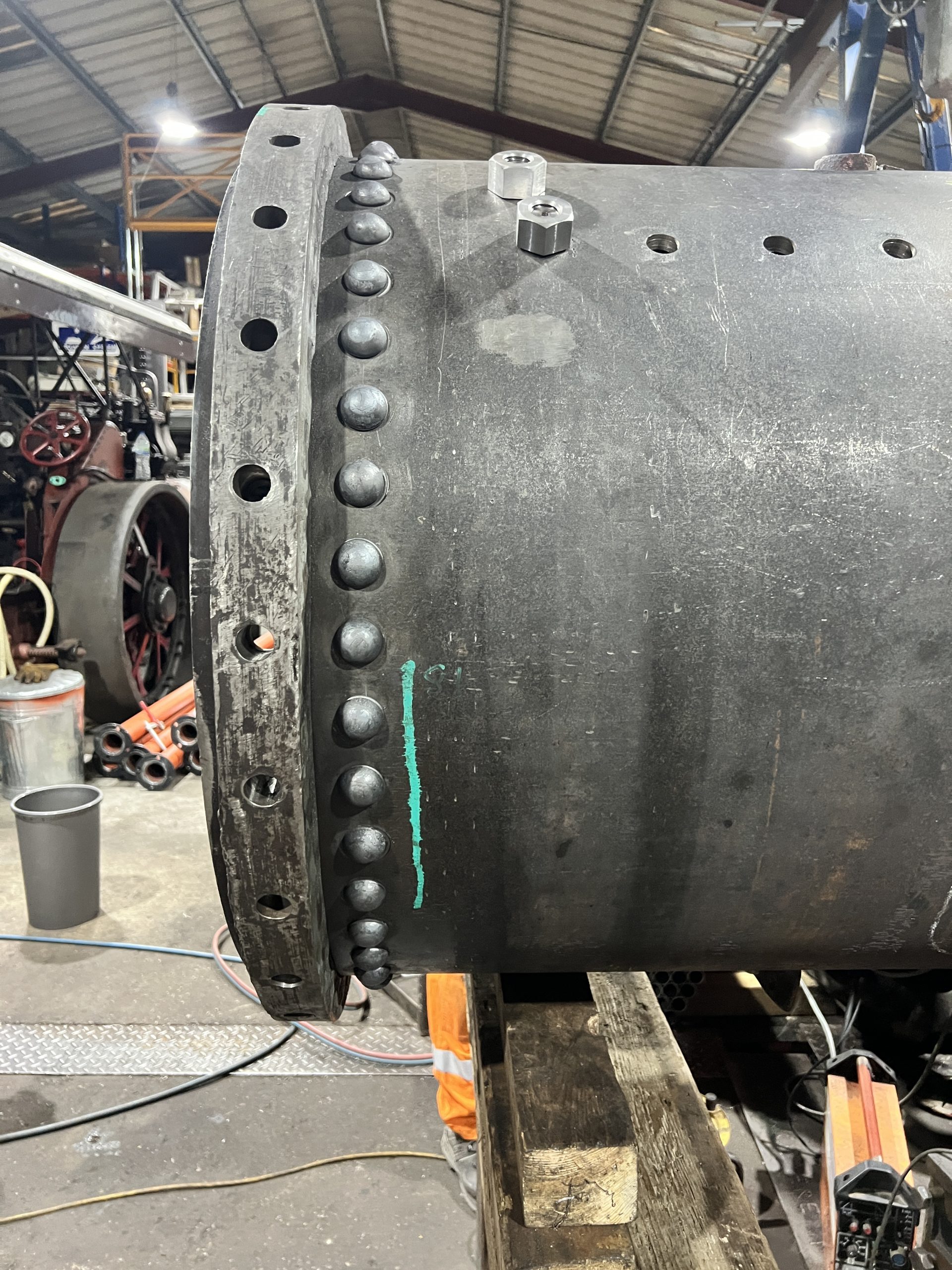

The last of the boiler rivets have gone in on Fowler 14712 Wilbur – Success!

The last of the boiler rivets have gone in on Fowler 14712 Wilbur. The final job is to fit a set of tubes before its hydraulic and then steam test. There has been a lot of work going into replacing the barrel after being off the road for a number of years. A ploughing engine certainly takes up a lot of room in the workshop but we will be said to see it leave.

Boiler Work & Restoration – Jubb Engineering & Training

Some more information on Boiler Rivets

Boiler rivets are typically made through a process called hot riveting. This process involves heating a metal rod (usually steel) until it is red-hot and malleable, then using a rivet hammer to shape one end into a head.

Here’s a step-by-step overview of how boiler rivets are made using hot riveting:

- Preparation of Rivet and Hole: The metal plates or parts that need to be joined (such as boiler plates) are first drilled with holes that are slightly larger in diameter than the boiler rivets. The holes are typically countersunk on one side to accommodate the rivet head.

- Heating the Rivet: The rivet is heated in a forge or furnace until it reaches a red-hot temperature. The exact temperature can vary depending on the type of metal being used and the specific application.

- Insertion of Rivet: The red-hot rivet is quickly placed into the hole in one of the metal parts that need to be joined. The tapered end of the rivet goes through the hole while the heated head sits on the opposite side.

- Forming the Head: A rivet hammer or pneumatic riveting gun is used to shape the rivet’s head. The hammering action deforms the head end, creating a larger, flat, and rounded surface that holds the parts together.

- Bucking: On the opposite side of the rivet, a second worker holds a tool known as a “back up tool” against the rivet’s point. The bucking bar acts as an anvil and provides support as the rivet is hammered. This prevents the rivet from becoming loose as the head is formed.

- Cooling and Setting: As the hot boiler rivets cool down, it contracts and tightens, pulling the joined metal parts together. This contraction creates a strong and secure bond between the parts.

- Finishing: Once the rivet has cooled and set, any excess material from the tapered end can be trimmed off, and the surface can be cleaned up if necessary.

Hot riveting was a commonly used method for joining metal components, especially in structural and heavy construction, like boilers, bridges, and ships, before the advent of modern welding techniques. It allowed for the creation of sturdy and reliable connections, but it has largely been replaced by welding due to the faster and more automated nature of welding processes.

It’s important to note that the use of hot riveting has significantly declined over the years, and modern manufacturing and construction processes now rely more on welding and other advanced methods however we at JE&T like to continue the time served methods of construction steam boilers.