New Pressure gauge calibration – Is yours right? 5% 10% 15% out?

Pressure Gauge Calibration

We had a 4.5″ Burrell in for its 10 year test. During the initial checks, the pressure gauge was found to be a long way out of calibration and not sitting on its 0psi peg. We initially thought the cheapest option was to replace it for a new one.

Upon arrival we found the new gauge to have the same problem and after speaking with the manufacturer, found they do not guarantee anything under a 2″ diameter gauge to anything better than 15%. for the working pressure of this engine, this meant the redline of 180psi could indicate anything between ~160 and 200psi. This isn’t really acceptable.

We set about finding an alternative solution and working with a local firm, have now got the gauge working correctly and calibrated with a tolerance of 1.6%. Just a little better. Get in touch for pressure gauge calibration & refurbishment of any gauges large or small. You will be surprised just how little this can cost.

check out our new website – https://www.jubbengineering.com

We do perform pressure gauge calibration along with all sorts of other instrument calibration as part our our sister companies business European Power Systems

How do pressure gauges work?

A pressure gauge is a device used to measure the pressure of a gas or liquid in a system. It works on the principle of elastic deformation of a material in response to applied pressure.

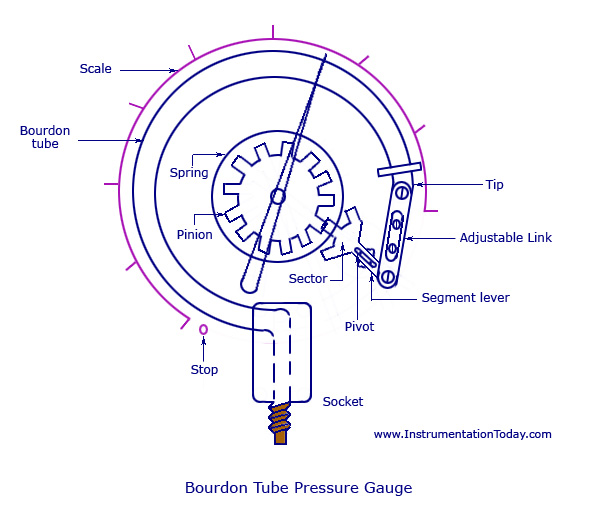

Most pressure gauges consist of a Bourdon tube, which is a curved metal tube that is closed at one end and open at the other. When pressure is applied to the open end of the tube, it causes the tube to straighten or deform elastically. This deformation is transmitted through a mechanical linkage to a pointer on a gauge dial, indicating the pressure value.

A Bourdon tube is a type of pressure sensing element used in many pressure measurement devices, such as gauges, switches, and transducers. It is a hollow, curved tube with an elliptical or circular cross-section that is closed at one end and open at the other.

When pressure is applied to the open end of the Bourdon tube, the tube tends to straighten or uncoil, which is called elastic deformation. The degree of deformation is proportional to the pressure applied. This deformation is transferred through a mechanical linkage to a pointer or other type of display, indicating the pressure value being measured. When the pressure gauge calibration is performed, it is the small adjustments to these components that are undertaken.

Bourdon tubes are typically made of metals such as bronze, brass, or stainless steel that have good elastic properties. The shape and size of the Bourdon tube depend on the pressure range and accuracy required. They can be used to measure both high and low-pressure ranges, depending on the design of the Bourdon tube and the instrument in which it is used.

Bourdon tubes are widely used in various industries, including oil and gas, chemical, pharmaceutical, and manufacturing, due to their reliability, durability, and accuracy in measuring pressure.

Pressure gauge calibration

Jubb Engineering for all your pressure gauge calibration needs